Company Profile

Lushan Yaxing Technology Development Co., Ltd. is a specialized company engaged in the research, design, production, sales, and engineering services of carbon materials for blast furnaces and submerged arc furnaces. The company is ISO 9001 International Quality Management System certified.

Adhering to the philosophy of "high-quality products and excellent services" based on customer needs, Lushan Yaxing collaborates with clients with integrity, striving to provide higher-quality carbon bricks and supporting refractory materials for the efficient and long-lasting operation of blast furnaces and submerged arc furnaces worldwide...

Product List

High thermal conductivity graphite brick

More >>

High thermal conductivity graphite brick

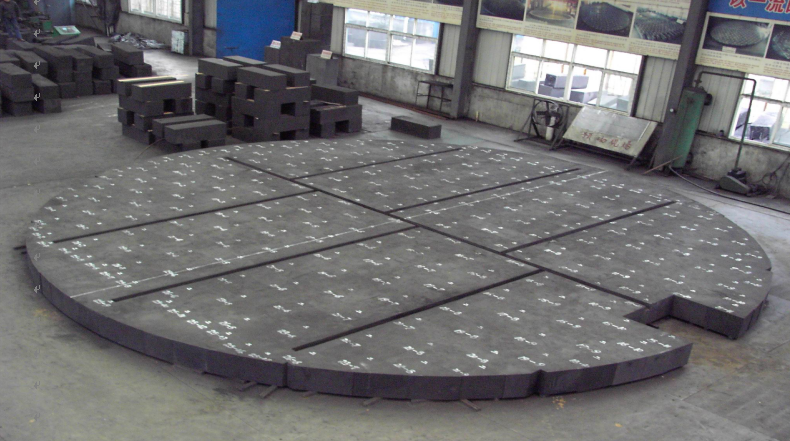

Graphite brick pre-assemble of 1800 m³ B.F.

Graphite brick of 2600 m³ B.F.

Small graphite brick

More >>

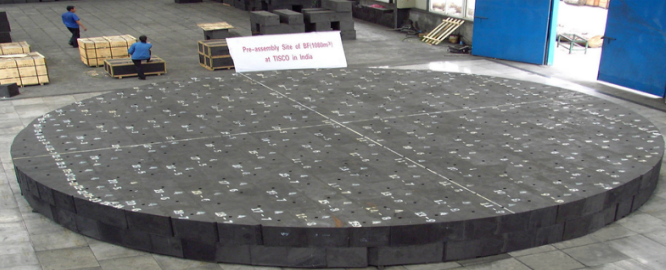

Graphite brick for E# B.F. of India Tata company

Small graphite brick for hearth

Small graphite brick

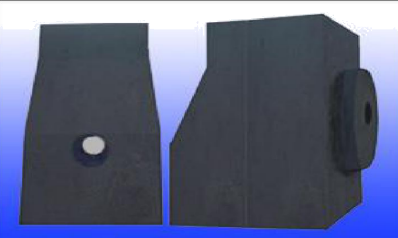

Semi-graphite carbon brick

More >>

Semi-graphite carbon brick with lead drainage grooves for 1,350 m³ B.F.

Semi-graphite carbon brick for 1080 m³ B.F.

Semi-graphite carbon brick for 2500 m³ B.F.

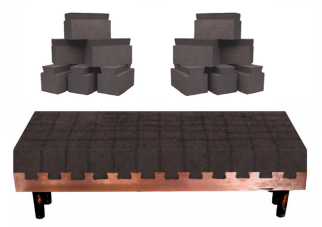

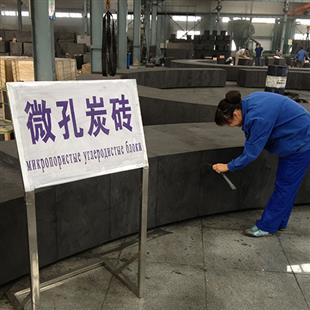

Microporous carbon brick

More >>

Microporous carbon brick. Pre-assemble of microporous carbon brick for 1000 m3 B.F.

Microporous carbon brick for 1080 m³ B.F.

Bottom used microporous carbon brick for 1513 m³ B

Ultra-microporous carbon brick

More >>

Pre-assemble of ultra-microporous carbon brick for

Ultra-microporous carbon brick for 1780 m³ B.F.

Ultra-microporous carbon brick for 2000 m³ B.F. bo

Carbon whole taphole brick

More >>

Ultra-microporous taphole brick

Ultra-microporous taphole brick

A, B Ultra-microporous taphole brick

High thermal conductivity carbon brick

More >>

High thermal conductivity carbon brick for 1780 m³

Pre-assemble high thermal conductivity carbon bloc

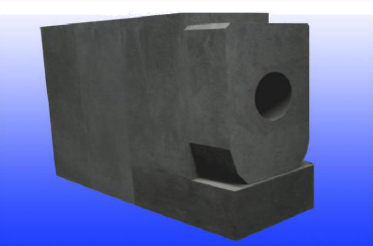

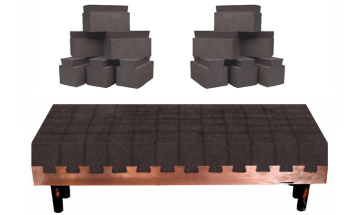

Submerged arc furnace special carbon brick

More >>

Submerged arc furnace special carbon brick

Submerged arc furnace special carbon brick

Submerged arc furnace special carbon brick

High strength, high thermal conductivity carbon ramming material

More >>

Carbon ramming mass

Carbon ramming mass

High thermal conductivity graphite castable

Blast Furnace Taphole Composite Brick

More >>

Other products

More >>

Self-bake carbon brick

Light carbon brick

Carbon electrode

Equipment Show

More >>

CNC machine for straight carbon brick

CNC machine for wedge carbon brick

Adjustable steel platform for pre-assemble

Testing center

More >>

Incoming raw material inspecting

Balance room

Vacuum drying oven

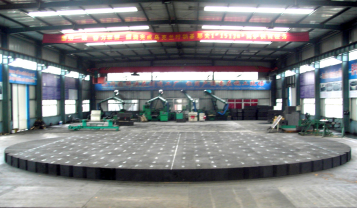

Preassemble inspecting

More >>

Pre-assemble inspecting

Pre-assemble inspecting

Pre-assemble inspecting

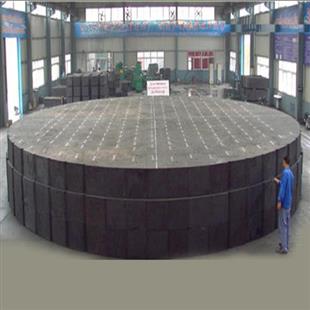

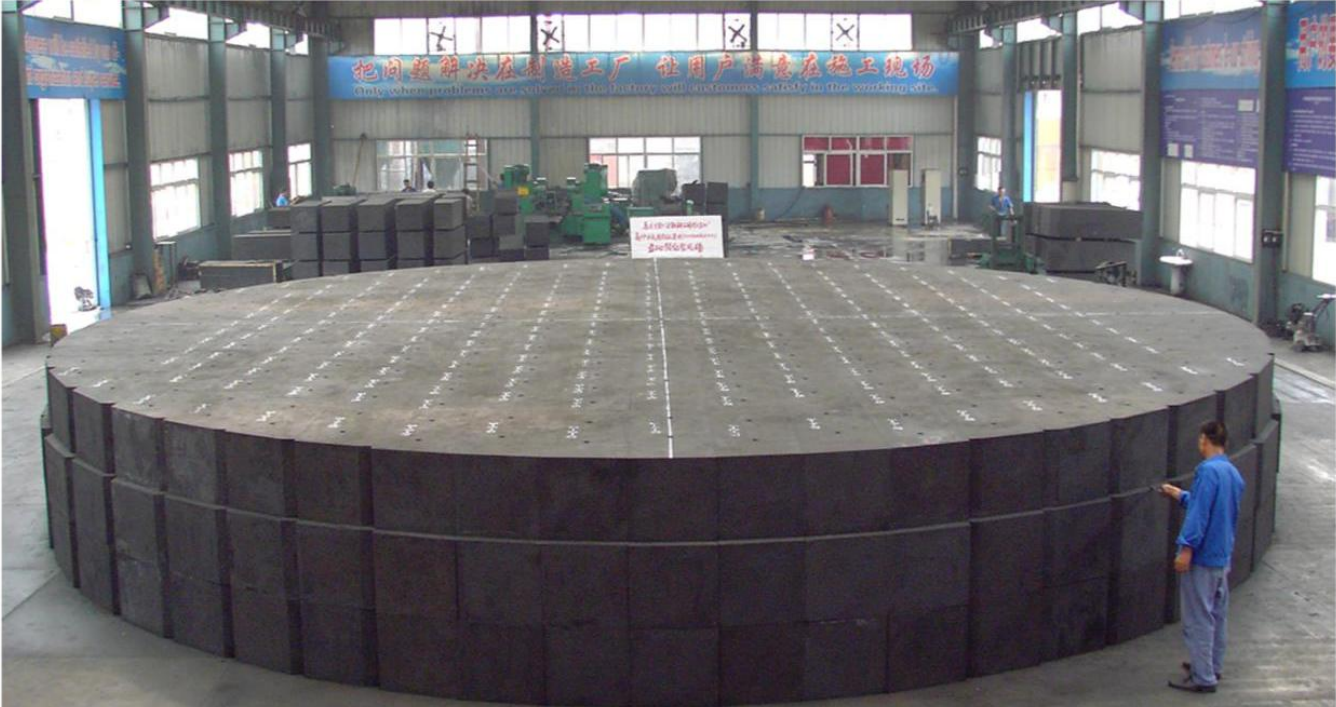

Preassembly of carbon resistant materials for large blast furnaces

More >>

The semi-graphite carbon carbide brick is used for single hole iron mouth brick, and it is used in E # 604m3 blast furnace of Tata iron and Steel Company of India(2006)

Ultra-microporous carbon brick combined with drilling taphole brick is used in 3400m³ blast furnace of Jinan Iron and steel company(2009)

Preassembly site of semi-graphite carbon silicon carbide roasted carbon brick for bottom of 2500m³ blast furnace in Shanghai Baosteel Group No.1 plant(1998)

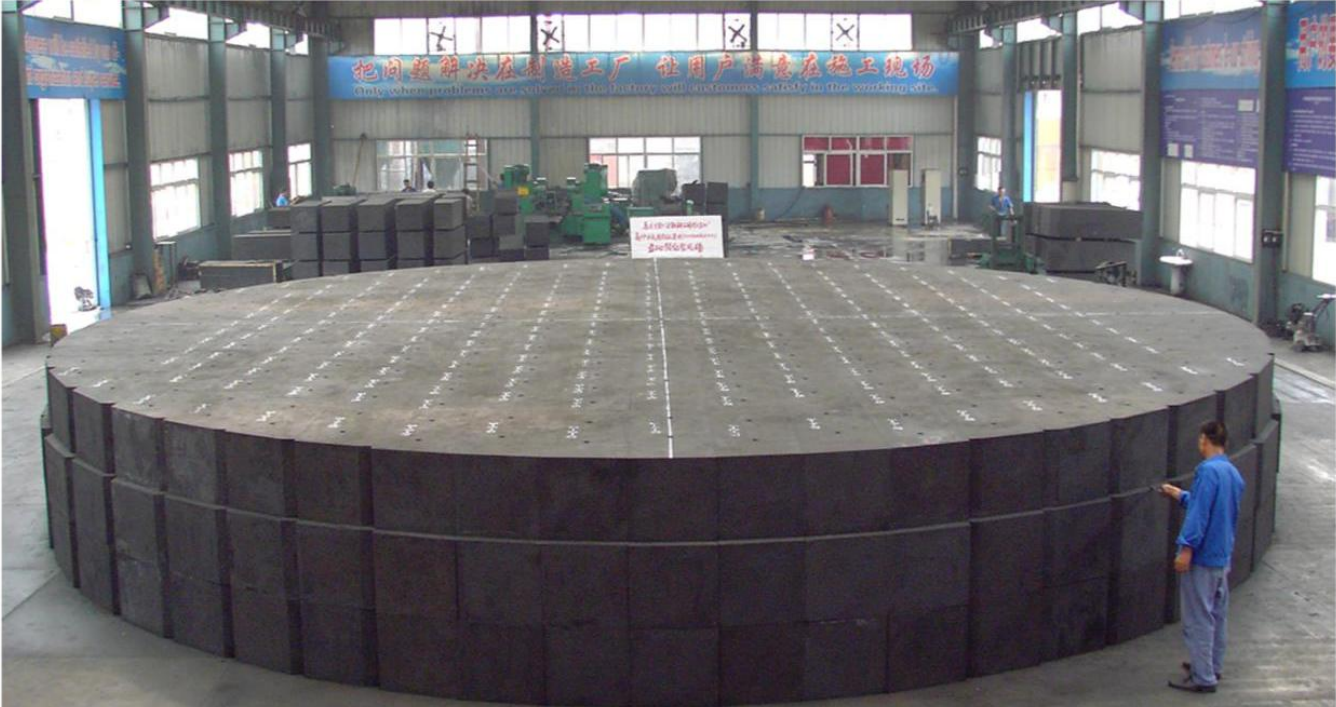

Preassembly site of carbon resistant materials for some large blast furnace(Graphite brick)

More >>

Preassembly site of graphite brick for bottom of new 1 × 3200m³ blast furnace in Liaoning Anshan Iron and steel company(2002)

The graphite brick preassembly site for the bottom of the new 1 × 3200m³ BF of Handan Iron and Steel Group in Hebei Province(2007)

Preassembly site of graphite brick for bottom of 7 × 3200m³ blast furnace in new Lipetsk, Russia(2008)

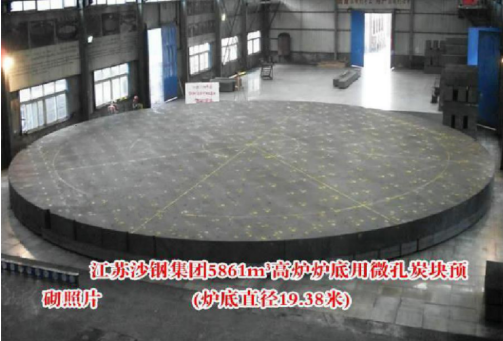

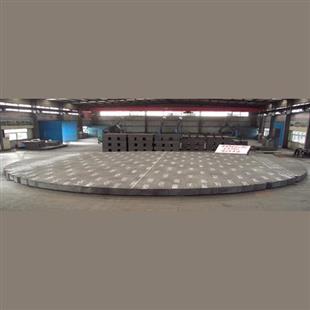

Preassembly site of carbon resistant materials for some large blast furnace(microporous carbon brick and ultra microporous carbon brick)

More >>

Preassembly site of ultra microporous carbon brick for hearth of 2200m³ blast furnace in ISA iron and Steel Company of India(2008) Three layers.

The preassembly site of 2500m³ BF bottom with microporous carbon brick is carried out in Zhangjiagang Shagang Group, Jiangsu Province(2002)

Preassembly site of ultra microporous carbon brick for hearth of 2518m³ blast furnace in Ispat iron and steel company, India(2008)

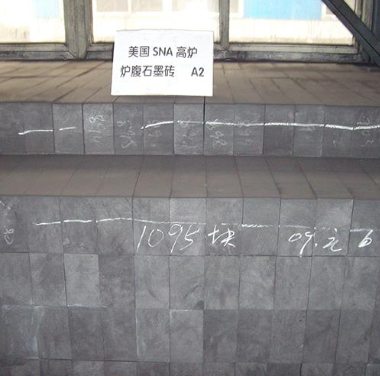

Preassembly site of carbon resistant materials for some large blast furnace(Graphite wall for hearth, inlaid graphite brick for copper cooling wall and graphite brick for copper cooling plate)

More >>

The preassembly site of graphite wall in hearth of E × 604m³ blast furnace in Tata iron and Steel Company of India(2006)

Graphite brick inlaid in copper cooling wall of l# 3000m³ blast furnace, Altos hornos iron and steel company, Mexico(2006)

Graphite brick for inlaying copper cooling stave of 2549m³ blast furnace in Asturias Steel Company of ArcelorMittal group of Spain(2008)

Some pre-assembly site of carbon bricks for submerged arc furnaces

More >>

Furnace bottom and hearth are pre-assembled on site

More >>

New system 4150m³ in Baotou Steel × 2 graphite brick, high thermal conductivity carbon brick

4350m³ graphite brick of Bensteel